Before starting with the topic, did you know copper was the first metal to be known to mankind? Lately, it has developed several uses in different streams. Technological advancements in the area of air conditioning are helping manufacturers to create items that are more energy-efficient and resourceful. While the cool breeze from Air Conditioners captivates you, a wide range of complex parts working symbiotically with it may leave you in awe! Copper pipe enhances the efficiency of air conditioning. Oops! You learned it for the first time! Copper coating in ac is too beneficial, confused keep reading!

Furthermore, copper comes with an additional benefit of natural antibacterial and bacteriostatic properties. It is also relevant in refrigeration and air conditioning systems. Remember, bacteria usually breed in these areas. Dangerous strains of bacteria and fungi become weaker and ineffective within a few hours when exposed to a copper surface. It is an effective process to bring down the curve for the number of diseases.

Let us explore the factors that make copper pipes stand out in air conditioning applications.

Table of Contents

The Role of Copper Coating in AC Systems:

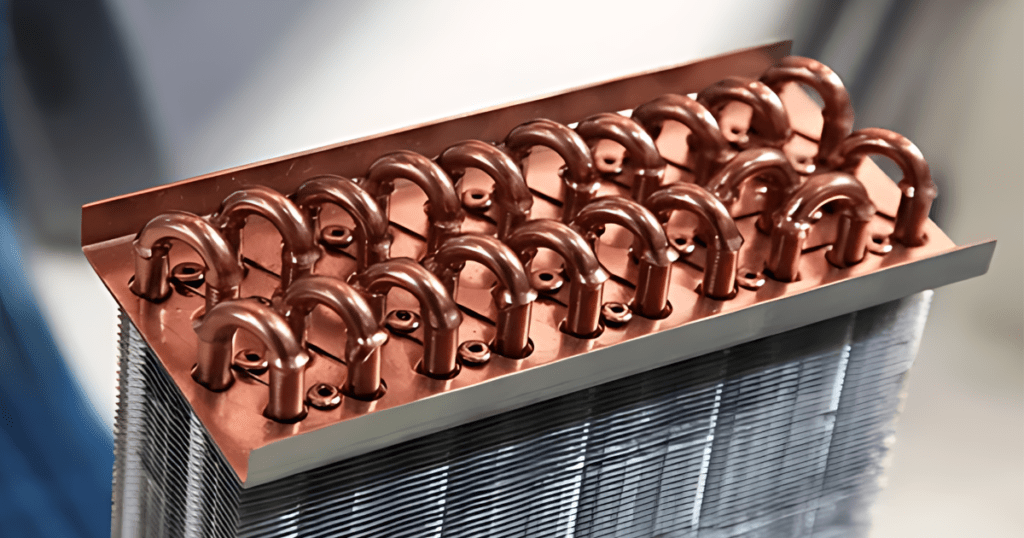

Copper is a main component in the manufacturing of air conditioners, and the heat exchanger is one of the primary applications. Here’s why you should choose the copper coating process over anything else:

Excellent Thermal Conductivity:

The copper material has an exceptionally high heat transmission ability and, hence, is an excellent substance for heat convection applications. Ac copper pipe coating or copper coils in AC systems absorb heat from the air inside your house efficiently and then release it outdoors, adding the cooling effect you were waiting for.

Quick Installation and Maintenance

Copper pipes are flexible and can be molded into the required shape, simplifying installation. I am sure this is what you are looking for, ultimately! Their compact size is good for the installation phase, making them lighter to work with. Do you get it? It will cost you less labor and time. The additional benefit here is the simple maintenance. If time-consuming repairs or major changes need to be done, technicians can immediately work with copper pipes, lowering the amount of downtime for the air conditioning system.

Corrosion Resistance:

Copper has the natural property to resist corrosion. Therefore, due to the copper coating on iron, it is corrosion-resistant and long-lasting in AC components. This resistance provides the coils with extra durability. Otherwise, it could be negatively affected by harsh weather conditions. The lifespan of the entire system is increased if you go with it. I am sure you already made up your mind.

Reduced Energy Loss

Copper pipes constitute the energy efficiency of air conditioning systems due to their heat conductivity. It diminishes the necessity of excess energy loss, which occurs within the pipes due to resistance. This makes the entire system smooth. Moreover, enhanced productivity allows the environment to save energy and helps create an environment where companies will spend less on operational costs.

Malleability and Formability:

Copper is a very suitable metal because it is malleable and ductile. It is often used to make complicated coil patterns and provide the maximum surface area to ensure good heat exchange. The capability of such flexibility in AC systems allows them to deliver the best performance.

Durability and Longevity

Air-conditioning systems function optimally with changing conditions such as temperature, pressure, and humidity. Copper pipes are a symbol of their durability and positiveness in resisting corrosion. This is remarkably true when we discuss air conditioning, where workers in the industry expose themselves to multitudinous moisture and variable climatic conditions all the time. The durability of copper pipes is far longer than any other type of pipes, resulting in a lower risk of leakage or improper functioning.

Excellent Heat Transfer Properties

Copper is one of the best heat conductors and is an ideal material for air conditioning systems. The capacity to quickly transfer and collect heat is an important feature in an air conditioner’s evaporator and condenser coils. The level of heat exchange is directly related to the system’s performance. Copper’s high heat-carrying ability helps it to transfer heat fast. In between, there can be temperature regulation that is quick and effective.

Let's cool down our expression with a wrap-up

When it comes to ac, and copper pipe coatings, copper is always at the top of the list of good choices. Thanks to their outstanding functions, which offer exceptional heat transfer and are very tough. They form an integral part of an air conditioning system to enable proper cooling. With the rapid development of technology, more comfort is added to our lives every day. Comfort is increasing with more sophisticated cooling technologies, and copper is definitely being added as a cool conductor.

Frequently Asked Questions

1. Do you know copper coating in AC is better than aluminum?

Copper coating in ac is always better than aluminum as it provides more strength, reliability, corrosion, and heat transfer. Economically it is better too!

2. How copper coating process can help in air conditioners?

The world-known part of any HVAC system has to be the refrigerant. The liquid chemical present in it is responsible for initiating the transfer of cold and hot air via this air conditioner. Copper pipes carry this chemical easily through the installed HVAC system.

3. How to protect my AC copper pipe coating?

You simply need to coat the whole equipment to get the best results. Coating at all the weak connections in the AC helps in early unit deterioration. It helps in complete corrosion protection.

4. What to expect when you do copper coating on iron?

You need to know about the chemistry to understand this. The moments when iron mixes with copper alloys, you can expect several advantages. You can enjoy several benefits apart from the strength it adds. It is useful when it comes to corrosion resistance. It does everything without influencing the conductivity. By the way, copper is already a very good heat conductor.